Answer:

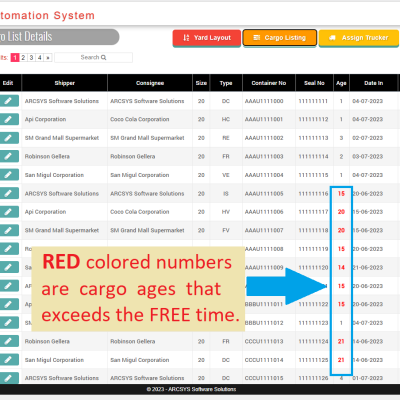

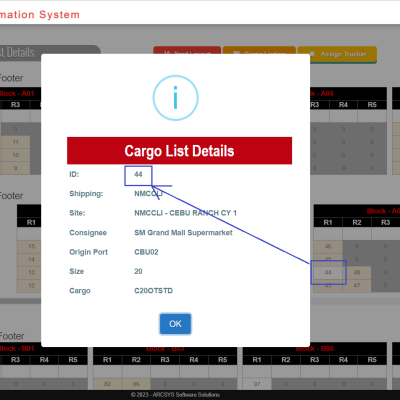

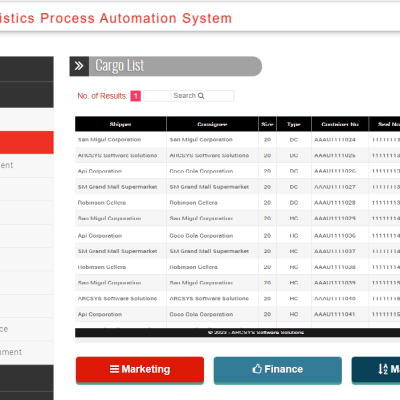

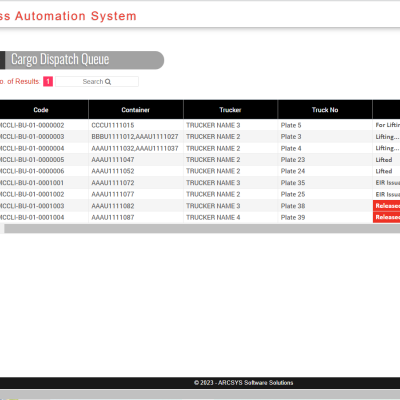

- Precision in Space Allocation: The system allows for the visualization of each individual cell in the yard, providing detailed information on space availability and usage. This precision in space allocation enables decision-makers to determine which cargo needs to be moved first, prioritizing based on scheduled releasing and receiving. Such precise management of space ensures optimal utilization of every available area in the facility.

- Identifying Minimal Movement Opportunities: By analyzing data, the system identifies containers that require the least movement. This approach minimizes unnecessary repositioning of containers, thereby reducing operational time and effort, and enhancing overall efficiency.

- Strategic Shifting to Low-Activity Cells: The system strategically moves cargoes or containers to cells that are characterized by minimal movements. This not only streamlines the arrangement of containers within the facility but also minimizes disruptions and maximizes the use of available space.

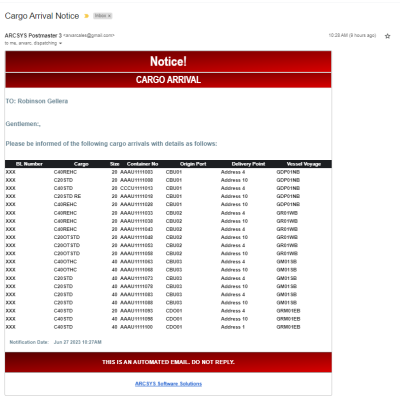

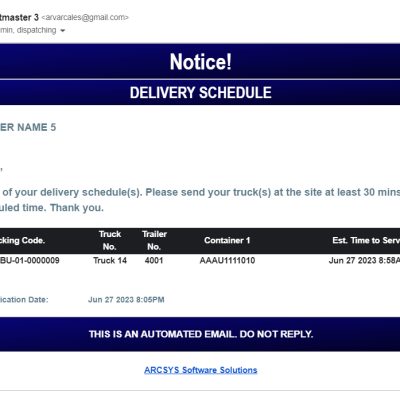

- Scheduled Truck Arrivals Aligned with Cargo Movements: The system schedules the arrival of trucks in alignment with the estimated schedule for the receipt or release of their cargoes. This synchronization ensures that trucks are not idly waiting for cargo, thereby reducing congestion both inside and outside the yard.

- Avoiding Unnecessary Equipment Movements: By optimizing container placement and minimizing the need for repositioning, the system significantly reduces the unnecessary movement of lifting equipment. This not only speeds up operations but also lowers wear and tear on equipment, contributing to reduced maintenance costs.

- Enhancing Operational Flow: The precision and accuracy of the system in managing cargo movements lead to a seamless operational flow. This efficiency translates into reduced waiting times for trucks, more efficient use of lifting equipment by the container yard operators, and an overall increase in throughput.

These demonstrate how your system’s focus on data-driven precision and strategic planning significantly enhances the utilization of both space and equipment in logistics operations. By optimizing every aspect of container movement and storage, the system effectively reduces operational costs and improves efficiency.