Answer:

"Our innovative logistics system is a comprehensive solution tailored to address the pressing challenges of inefficiency and high operational costs in the logistics and transportation industry. This system is a groundbreaking approach, leveraging cutting-edge technologies and smart strategies to streamline logistics operations.

Key features of the system include:

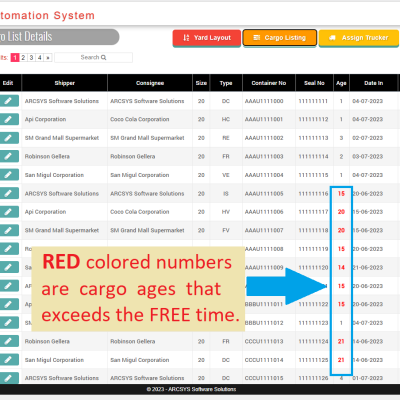

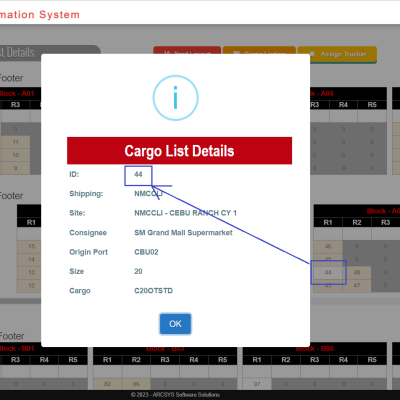

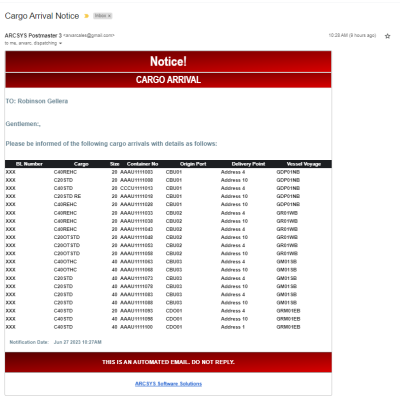

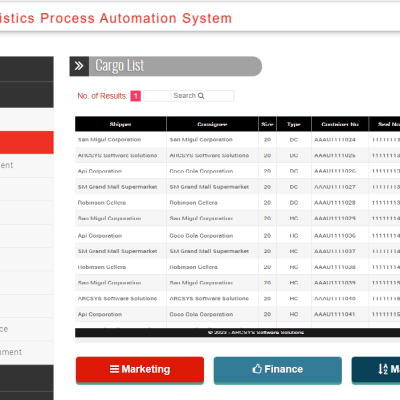

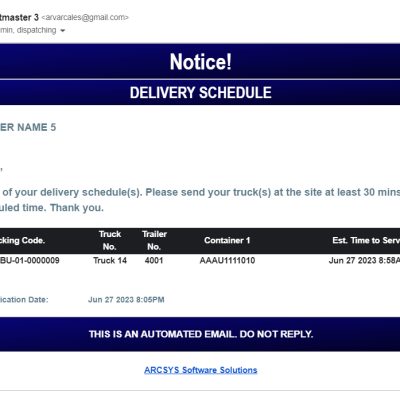

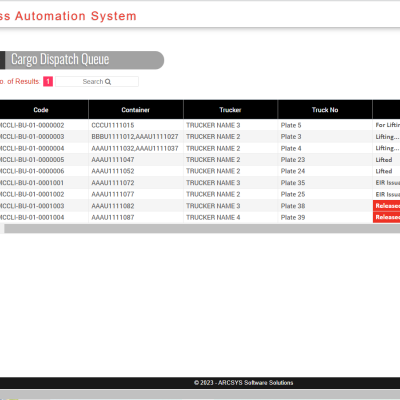

- Improved Dispatch Efficiency: The system enhances the efficiency of the dispatch process, significantly reducing time and errors in both documentation and physical movements.

- Elimination of Queues and Congestion: By intelligently managing schedules and movements, the system eliminates queue build-ups, both in documentation processes and in physical operations.

- Increased Throughput and Space Utilization: The streamlined processes result in increased throughput in container yards (CYs), depots, and storage facilities, leading to better space capacity and utilization.

- Reduced Operational Costs: The system plays a crucial role in minimizing operational expenses for CY and depot operators by reducing or eliminating unnecessary movements, directly impacting fuel and maintenance costs.

- Enhanced Productivity and Revenue: By optimizing operations, the system boosts the productivity of CY and depot operators, which translates into increased revenue for these businesses.

- Non-Quantifiable Benefits: Beyond measurable improvements, the system offers significant non-quantifiable advantages, such as claims prevention and enhanced operational reliability.

It is not just about managing logistics; it represents a transformative approach to redefine efficiency, cost-effectiveness, and reliability in the logistics sector. It positions businesses for sustainable success in a competitive and dynamic market environment."